Tenon offers a comprehensive range of horizontal glass washers, from easy to install and operate entry level machines to complex PLC controlled equipment that can be integrated into full production lines.

All of our equipment has long term reliability and durability – with features that can be tailored to suit your requirements – as well as high washing speeds, self-diagnosis and alarm functions, energy and noise reduction options, and water filter systems.

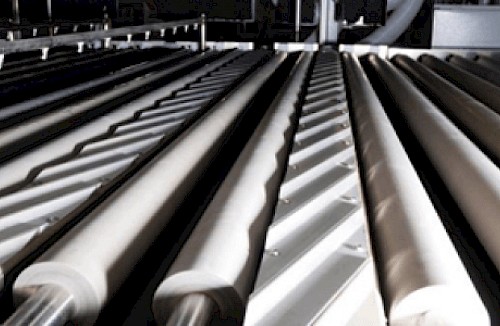

Tenon Horizontal Washers

Our Tenon washers come with inlet roller conveyor, washing section with pre-rinse, three pairs of brushes, drying section with two pairs of air knives, heated water system, and sound–proofed air filtering to reduce noise level.

The Horizontal Washer works without any detergents, they are equipped with an energy saving system so that when the conveyor stops, the water and air stops. When there is no glass indexing through the machine, all the steps will automatically shut down.

All contact points with water are made of stainless steel including the steel support and bearings for lower rollers. These machines are designed to work as a stand-alone washer, or they can be integrated in line with our Tenon seamer. They can be fitted to other processing line such as double edgers.

Some key features are:

- Strong welded stainless steel construction

- High production capacity up to 10m/min

- Quiet operation and extremely energy efficient

- Inverter for conveyor rollers drive with digital display for speed

- Upper prewashing

- Washer raises to 500mm for easy cleaning

- Automatic thickness adjustment as an option

- Simplified maintenance with ‘easy access’ tanks

Tenon washers give perfect cleaning and drying of glass up to 3300mm wide!

Innovative Flat Glass Solutions

Require a quote? Need to speak to us?

- Call: 00 44 (0)1359 256143

- sales@flatglasssolutions.com