Our sealing robots are highly efficient and produce a consistent and excellent quality sealing performance.

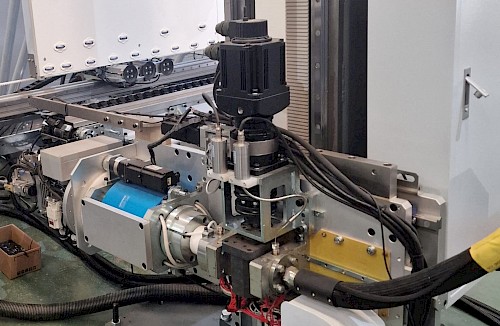

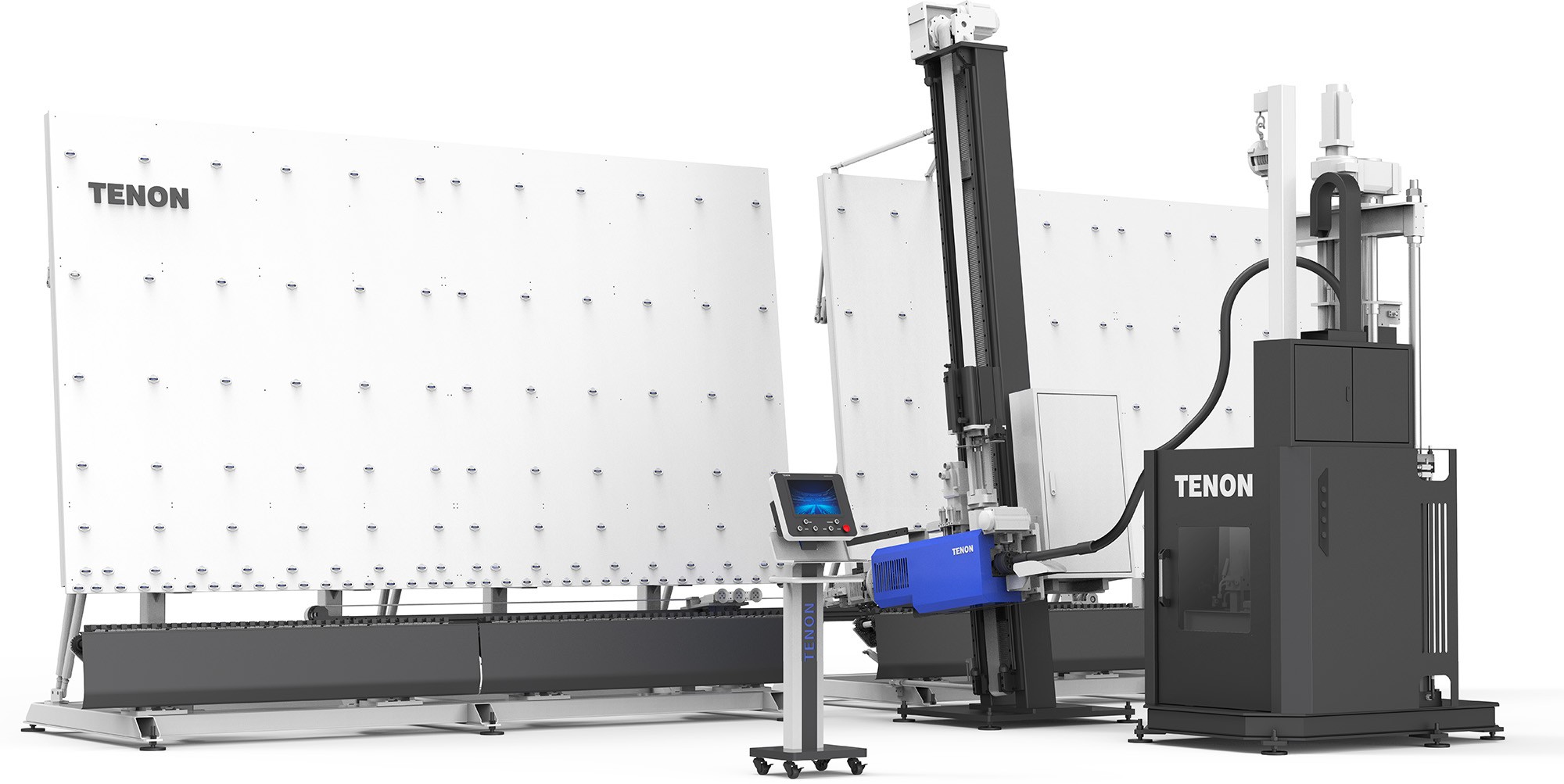

Tenon’s Automatic Sealing Robot can operate with Hot Melt, Silicon, and Two-part Material and are compatible with many existing manufacturers IG Lines or suitable for processing off-line. Whether they are integrated with a unit line or stand-alone, they will ensure a considerable reduction of production times and will also benefit the customer by producing a higher precision of sealing while reducing waste material and eliminating time delays.

View Brochure

Sealing Robot

Intuitive, simple and ergonomic sealing robots designed with the customer in mind. The machine adopts a touch screen interface for easy-to-use functionality and repeatable memory functions. The operator can control the functions of the machine simply and easily during all phases of the process. The simple yet modern design assists the operator to work easily and comfortably. The finished glass is transported on special Vee pads which support the glass edge and not the sealed cavity.

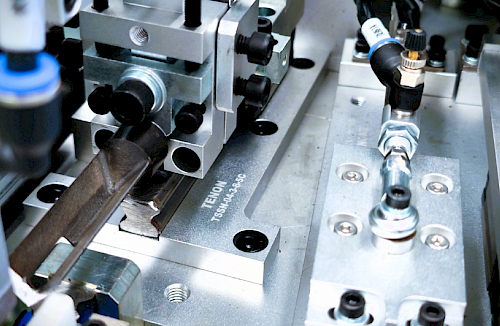

Accurate and precise, the rotating nozzle head fills the edge of the unit with fast and defined dosages of filler which is electronically controlled. The mixing ratio is predetermined and mechanically locked. Feeding and dispensing of the sealant is automatic according to the width and depth of the fill area. The nozzle is automatically centred which means the sealing space is evenly filled and the electronic depth scanning device continuously calculates the amount of material needed.

We offer 3 models of the sealing robot:

- SR2000

- SR2500

- SR3000

Specifications

| Model | SR2000 | SR2500 | SR3000 |

| Maximum Glass Size | 2800mm x 2000mm | 3300mm x 2500mm | 6300mm x 3000mm |

| IGU Thickness | 12-40mm | 12-40mm | 12-40mm |

| Sealing Width | 6-30mm | 6-30mm | 6-30mm |

| Sealing Speed | Up to 12m/min | Up to 12m/min | Up to 12m/min |

Innovative Flat Glass Solutions

Require a quote? Need to speak to us?

- Call: 00 44 (0)1359 256143

- sales@flatglasssolutions.com